95

2.

The pump should be so selected as to have a maximum efficiency at

the operating head likely to be obtained during major part of the year.

3.

For the site condition of head and discharge the centrifugal pump should

have the following minimum efficiency in the HP range given below :

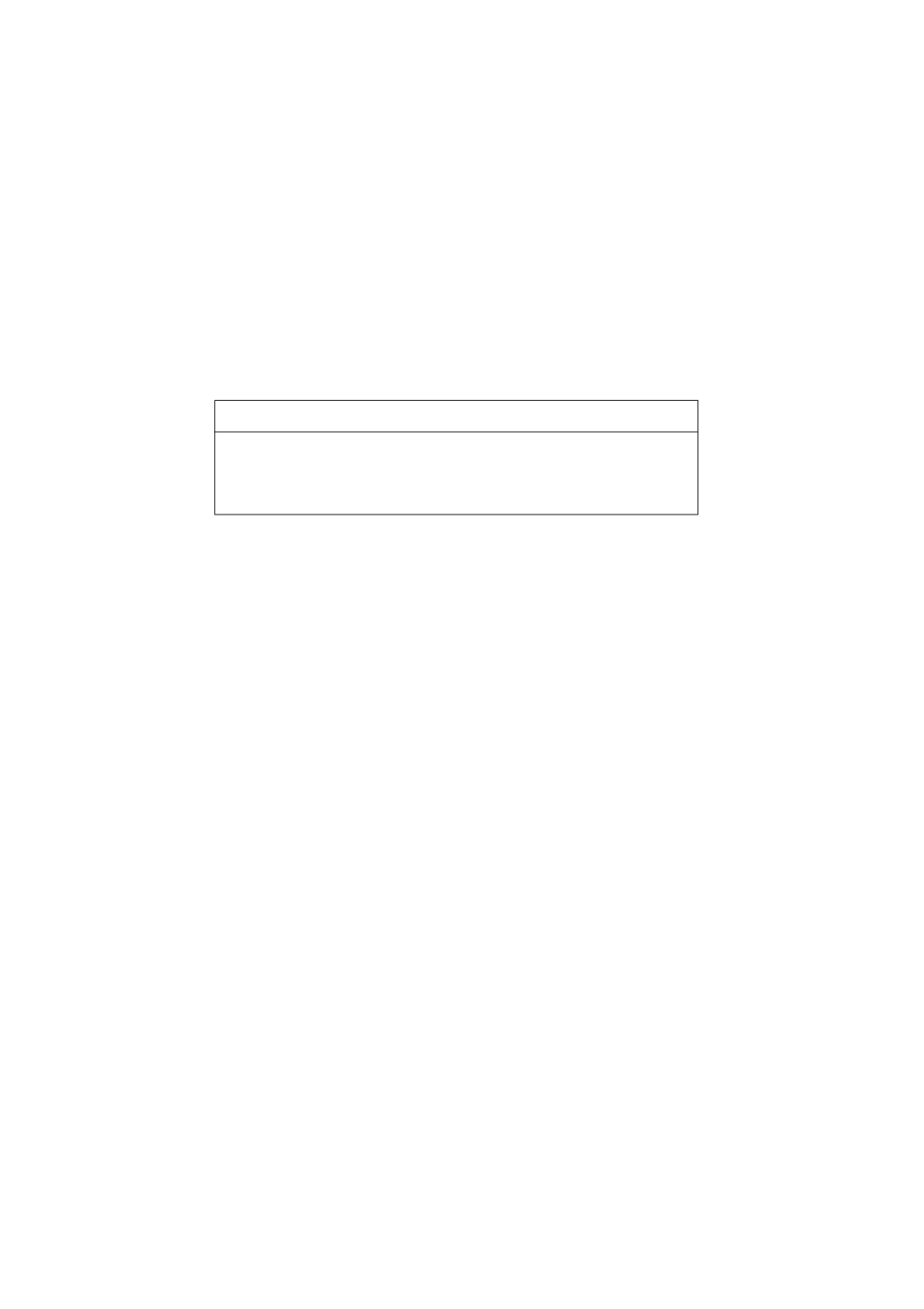

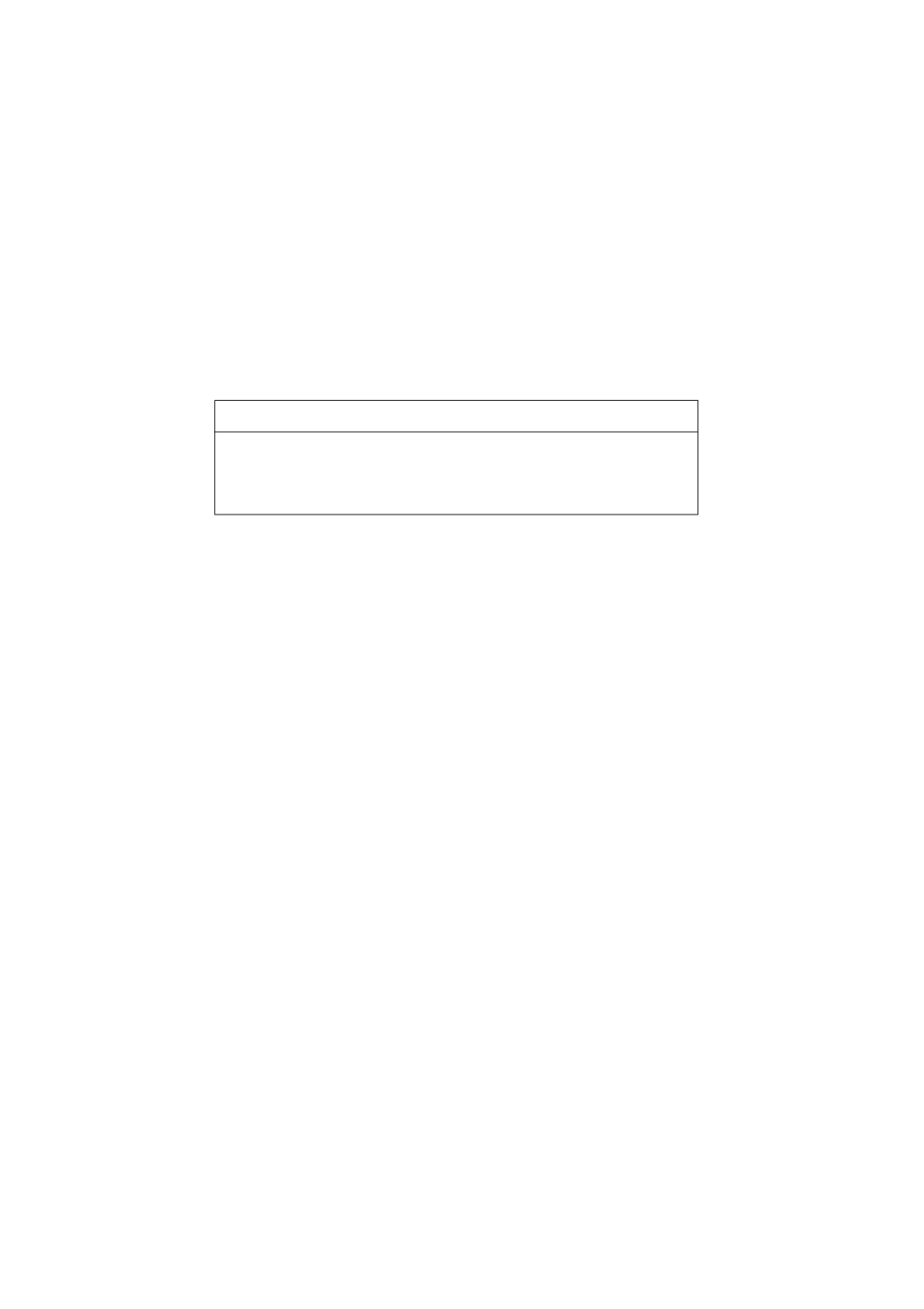

Table 6.9 : Minimum required efficiency of puymp [NABARD, 1989]

HP of the Pump

Minimum required efficiency(%)

Upto 2

50

2 to 4

55

4 to 10

60

4.

On practical considerations the vertical distance between the lowered

water level when the pump is working and the centerline of the pump

should not be more than 4.5 m excluding friction losses.

5.

The pump should have ISI Certification mark.

6.

The pump which has a maximum efficiency for the head and discharge

required at site should be selected from a group of ISI marked pumps

available locally. This criteria should override other considerations.

7.

Only those pumps for which genuine spare parts are readily available

should be preferred.

8.

Only those pumps for which after sales service is easily and effectively

available should be preferred.

9.

The pumps which have reputation of giving efficient and trouble free

service should be preferred.

It is now mandatory that it should conform the specification laid under

IS10804 : 1986.